HDSB - Solvent Based Epoxy Coating

-

$0.00

Videos and Instructions

FREQUENTLY ASKED QUESTIONS

Large Project? Get a Quote Here

HDSB is a two component solvent based epoxy coating that exhibits excellent characteristics for abrasion resistance, chemical resistance, and substrate penetration. This product is suitable as a primer for high build coatings, urethane or as a stand-alone coating. Coverage: 267 to 320 sq ft per gallon depending on the porosity of substrate.

RECOMMENDED FOR: Recommended priming or coating concrete, wood or steel. This product can withstand exposure too many common solvents and chemicals.

Cure Schedule: 70 degrees:

Pot Life - 2 gallon volume: 3 to 5 hours

Tack Free / Dry to Touch): 2 to 4 hours

Recoat / Topcoat: 4 to 6 hours

Light Foot Traffic: 16 to 24 hours

Full Cure: 2 to 7 days

Application Temperature: 40-90°F

SOLIDS BY WEIGHT: Mixed= 65% (+, - 2%)

SOLIDS BY VOLUME: Mixed= 52% (+, - 2%)

VOLATILE ORGANIC CONTENT:

Part A= 3.43 pounds per gallon/Part B= 3.75

pounds per gallon

VOC mixed < 427 g/l

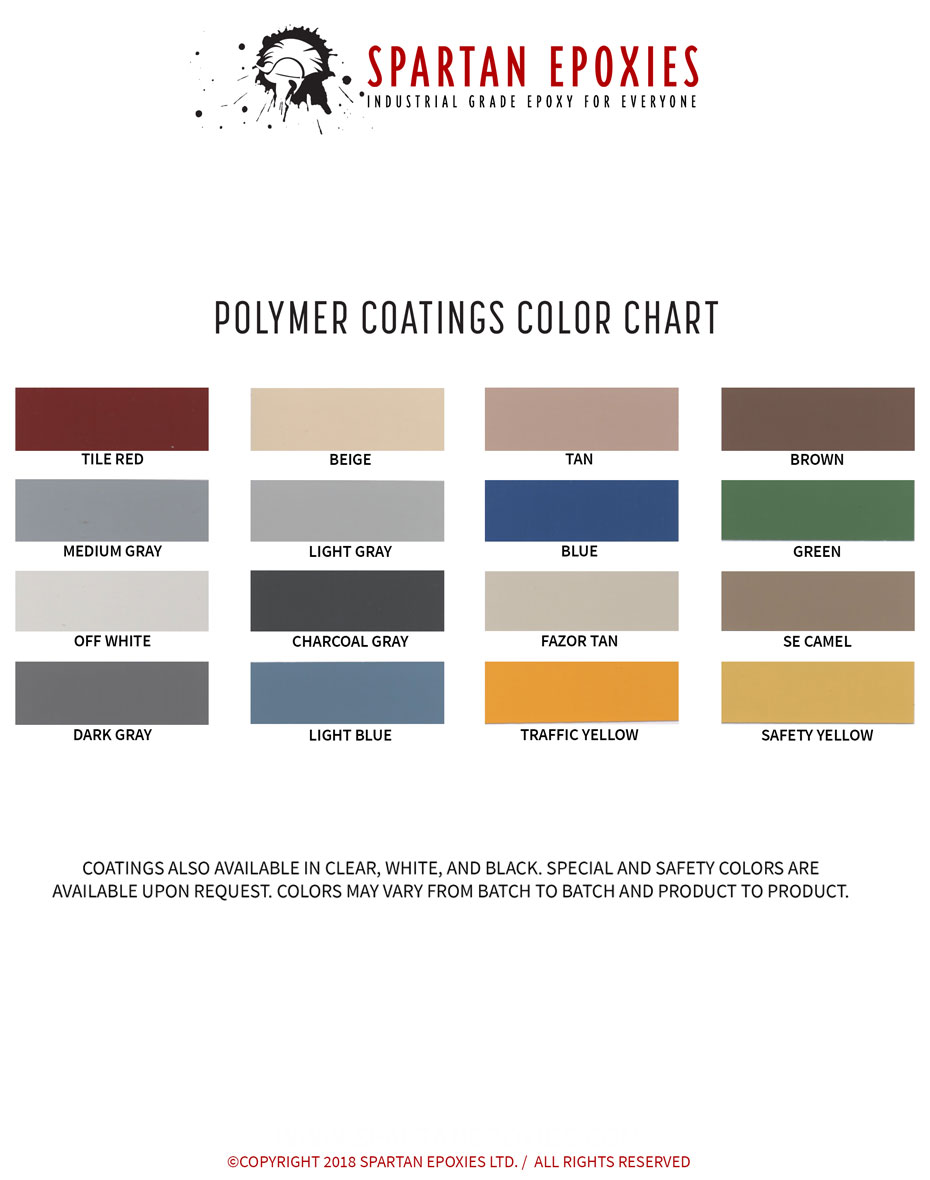

STANDARD COLORS: White, off white, light gray, medium gray, tile red, and beige.

RECOMMENDED FILM THICKNESS: 5- 6 mils per coat wet thickness (yields 3 mils dry)

COVERAGE PER GALLON: 267 to 320 square feet @ 5-6 mils wet thickness

PACKAGING INFORMATION: Quart, 2 gallon and 10 gallon kits (volume approx.),

2 gal kit= 1 gallon part A (8.5#/gal) (weights ap proximate) and 1 gal. Part B (11.0#/gal)

(weights approximate)

MIX RATIO: 1 part A to 1 part B by volume

SHELF LIFE: 1 year

FINISH CHARACTERISTICS: Satin gloss (30-60 at 60 degrees @ glossmeter)

ABRASION RESISTANCE: Taber abrasor CS-17 calibrase wheel with 1000 gram total load and 500 cycles = 30.2 mg loss

IMPACT RESISTANCE: Gardner Impact, direct= 50 in. lb. (passed)

FLEXIBILITY: No cracks on a 1/8” mandrel

ADHESION: 375 psi @ elcometer

(Concrete failure, no delamination)

VISCOSITY: Mixed = 300-500 cps (typical)

DOT CLASSIFICATIONS:

Part A “FLAMMABLE LIQUID N.O.S., 3, UN1993, P GIII”

Part B “FLAMMABLE LIQUID N.O.S., 3, UN1993, P GIII”

PRIMER: None required

TOPCOAT: Optional, Many products are suitable as topcoats including multiple coats of this product. For added chemical resistance, color stability or UV stability, topcoat with a suitable aliphatic urethane such as HPU, TC92, HDI, PC66, HP44, and many more. Ask a Spartan Epoxies Coatings Expert for additional information.

Tags: Primer