RapidXT - One Day Flexible Polymer Coating - Interior or Exterior

-

$0.00

Videos and Instructions

FREQUENTLY ASKED QUESTIONS

Large Project? Get a Quote Here

RapidXT is a two-component, fast-set, high solids, VOC-compliant, flexible polymer formulation designed primarily as a primer/basecoat across diverse flooring settings. RapidXT offers quick tack-free times while maintaining sufficient workability which enables a 1-day flooring solution. Apply a pigmented polyaspartic for a 1-Day neat system. RapidXT can function solely or alongside various decorative components such as quartz, micas, or vinyl paint chips. RapidXT is also a great choice for exterior flooring applications like patios, or pool decks. An accelerator option is available for maintaining curing times in colder conditions. Speak to a Spartan Epoxies Expert today to learn more about the capabilities of RapidXT.

Coverage Rate: 100 - 200 square feet per gallon @ 8-16 mils.

Cure Schedule: 70 degrees:

Pot Life - (150 gram mass): 15 to 25 mins

Tack Free (dry to touch): 3 to 6 hours

Recoat / Topcoat: 3 to 6 hours

Light Foot Traffic: 8 to 12 hours

Full Cure: 3 to 5 days

Application Temperature:

40 - 90 Degrees F with relative humidity below 90%

SOLIDS BY WEIGHT: 99%

VOLATILE ORGANIC CONTENT: 11 g/l

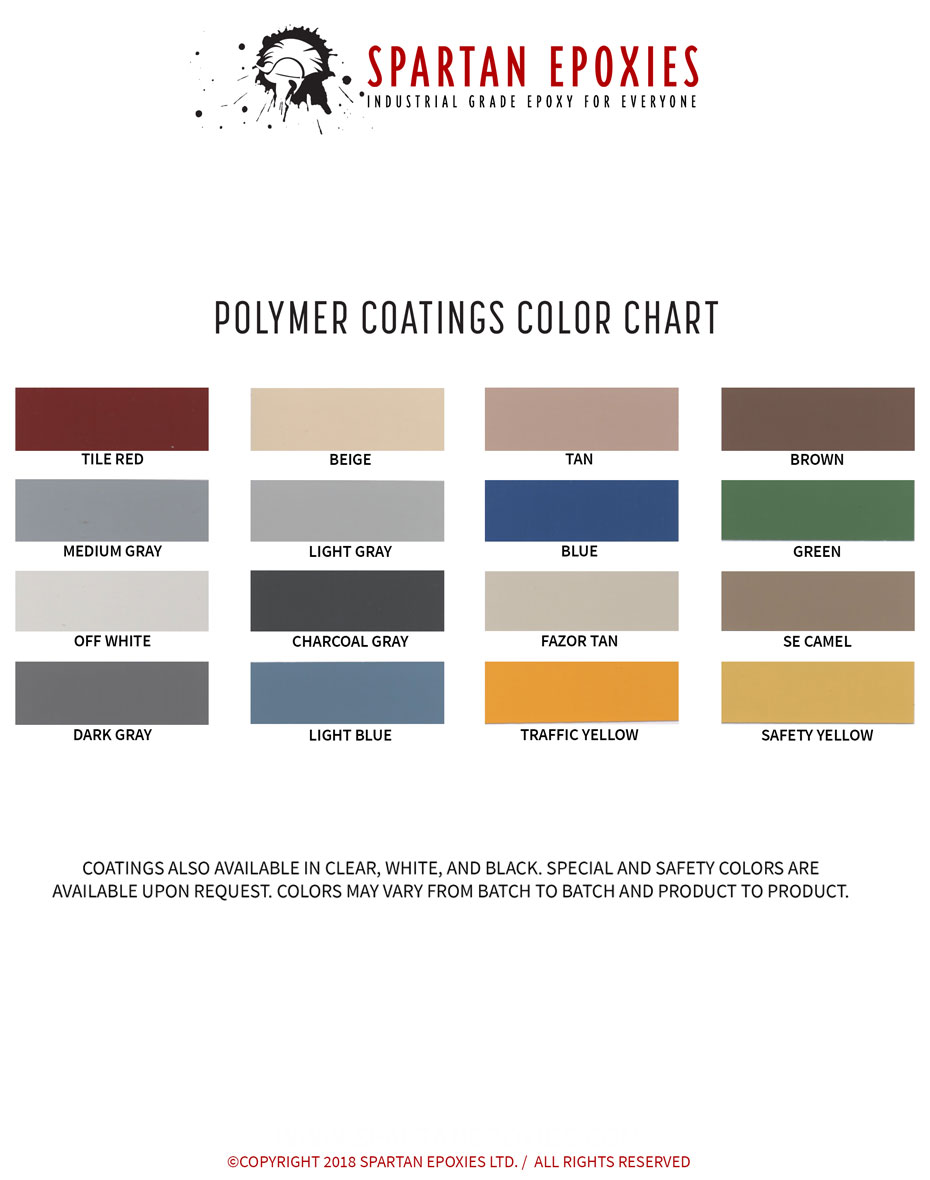

COLORS AVAILABLE: Gray/Beige/Black

RECOMMENDED THICKNESS: 8-16 mils

COVERAGE: 100 - 200 square feet per gallon @ 8-16 mils

PACKAGING: Available in 3 different kit sizes: (1 ¼ gallon, 2 ½ gallon & 5 gallon)

MIX RATIO: 4 to 1 by volume

SHELF LIFE: 6 months in unopened containers properly stored at normal room temperature. (mix before use)

HARDNESS: 20-30 Shore D typical

TENSILE STRENGTH: 1,200 psi

ELONGATION (ESTIMATED): 50-100%

IMPACT RESISTANCE: Excellent

ABRASION RESISTANCE: 20 mg loss with a 1000 gram total load at 1000 revolutions with a CS17 wheel

ADHESION: 370 psi (elcometer) – no delamination/concrete failure

VISCOSITY: Mixed= 500 cps – 1,400 cps (typical)

DOT CLASSIFICATIONS: Part A “not regulated” Part B “not regulated”

Chemical Resistance:

Varies by reagent, from temporary splash exposure to long-term immersion based on specific chemicals.

Application Notes:

• Primer not required.

• A topcoat with UV stability (e.g., polyurethane or polyaspartic) recommended.

• Not UV color stable; environmental factors may affect color stability.

• Intended as a flexible protective membrane, not a finish coat; surface irregularities may occur.

• Substrate temperature must be at least 5°F above dew point.

• New concrete must cure for a minimum of 30 days.

• Product must be mixed thoroughly.

• Conduct a trial installation off-site to familiarize with product properties.

Limitations:

• Color and texture may vary between batches.

• Ensure environmental conditions are suitable for application to prevent issues related to humidity, chemical exposure, or lighting.

Additional Information:

For extensive chemical resistance data and specific application instructions, consult with your Spartan Epoxies Expert.