METALLIC EPOXY - 800 FT² KIT

-

$1,747.90

Videos and Instructions

FREQUENTLY ASKED QUESTIONS

Large Project? Get a Quote Here

Our 800 FT² Metallic Epoxy Flooring Kit is the perfect option to save money on your next flooring project. This Metallic Epoxy kit includes 3 gallons of HDWB Epoxy Primer, and 12 Gallons of Metallic Epoxy. Since every need is unique, we sell urethanes separately as each urethane we offer are specific to the requirements of your Metallic Epoxy project.

Choose Spartan Epoxies Metallic Epoxy for a seamless, custom floor. As America's top choice, our product is freshly made to order, using high-quality materials from the USA. With Spartan Epoxies, you receive expert guidance throughout the process. While cheaper alternatives, like those made in China, might initially look similar, they often suffer from discoloration, chipping, fading, yellowing, peeling, and failure within months. This results in wasted effort and the need to redo everything. Don't compromise quality for cost. Spartan Epoxies ensures your investment in high-performance, industrial-grade resinous flooring pays off.

This kit is marked on sale from $1,912.90 to $1747.90! That's $165.00 in savings!

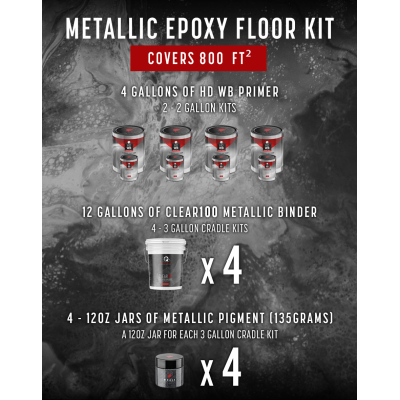

What's Included:

• EPOXY PRIMER: 3 Gallons of HDWB - Waterborne Epoxy Primer - Covers 267 FT² per gallon @ 6 mils.. 3 gallons covers 801 FT². (Upgrade to 6 Gallons of HD Pro High Solids Epoxy in this kit for a higher build system).

• METALLIC EPOXY: 12 Gallons of CLEAR100 - Metallic Binder - 70 sq ft @ 21 to 24 mils THICK COATING covers 800 sq ft! - (4) - 3 Gallon Kits of CLEAR100.

• 4 Containers (135 grams) of your choice of 50 of our rich, 3D - Metallic Pigment Powders. Customize your Metallic Epoxy Floor by selecting a 12oz metallic pigment for each of your 3 gallon kits of CLEAR100. Also, add our sparkle additive to give it that extra pop! Use the swatch on the first option marked "Metallic" to view all of our metallic pigment choices. Then, select the color you want from metallic 2, metallic 3, and metallic 4. Which represents the 4 - 3 gallon kits of CLEAR100. If you need help configuring your kit, please call or start a chat today!

Upgrade Primer to HD Pro

When you select this option, you will receive 6 gallons. Which will provide enough epoxy for a 12 mil primer coat. You can upgrade this kit's primer from our Waterborne Primer (HD WB) to our High Solids Epoxy Base - HD PRO. HD PRO is a high build epoxy, that provides better coverage, better adhesion, even more durability, and so much more. HD PRO is a versatile product that can be used as a stand alone product, and is present throughout our core products lineup. It's used in warehouses, labs, and in so many other environments where a high impact, high solids system is needed.

Our Metallic Epoxy kit is going to make any floor the highlight of your home or business. Also, you get free application support by a true trained professional. Try to find that anywhere else!

Surface prep is the most important part of your project. Tools not included in this kit. We recommend a 26" Kraft squeegee, 3/8" nap roller for the primer and top coat (top coat not included in kit), 3/16" nap roller cover for the metallic (if you choose to use a roller at all), spiked shoes for each person helping, and 3" chip brushes for each layer of material. If you need help configuring your kit, call or start a chat with a Spartan Epoxies coating expert.

Urethane Top Coat (Clear Coat)

We always recommend applying a urethane top coat (clear coat) over any epoxy floor. This will protect your investment for years to come. Especially if you are applying where there will be vehicular traffic. We offer a range of urethane top coats and each application is unique so please ask a Spartan Epoxies Expert which top coat is best for your application.

NEW!

Try our new WB ONE Acyrlic Urethane. Unlike traditional urethanes which has an orange peel texture, WB One has a beautiful, high gloss, smooth finish! It's also one of our most inexpensive urethanes we offer! However, if you plan on applying a metallic epoxy floor in an area for vehicle traffic, we would recommend applying TC92, HPU, or HDI. We also offer polyaspartic urethanes. Typically we recommend HP44 Polyaspartic for metallic epoxy floors. If you need help, please call and speak to a Spartan Epoxies coating expert, or start a chat below.

Tools Required to Complete Your Metallic Epoxy Flooring Project:

• Spiked Shoes

• Kraft Squeegee

• 3/8" Nap Roller Covers for Primer and Topcoat

• 3/16" Nap Roller Covers for Metallic Epoxy if you plan to swirl for marbled effect

• 9" or 18" Roller Frames

• 3" Chip Brushes (typically for primer and topcoat edging

• Paint Tray for Primer and Topcoat

Shipping Information

This kit could get shipped via freight. Please know that if you use their lift gate service it's possible that you could get charged an extra fee once your order gets delivered. Please make sure to note in comments section of your order if are shipping to a home or business.

Preparation, Mixing and Installation Instructions for Primer / Base - HD PRO High Solids System. This kit includes HD PRO, our superior and most versatile base system.

1) PRODUCT STORAGE: Store product in an area so as to bring the material to normal room temperature before using. Continuous storage should be between 60 and 90 degrees F. Low temperatures or great temperature fluctuations may cause crystallization.

2) SURFACE PREPARATION: The most suitable surface preparation would be a fine brush blast (shot blast) to remove all laitance and provide a suitable profile. All dirt, foreign contaminants, oil, and laitance must be removed to assure a trouble free bond to the substrate. A test should be made to determine that the substrate (Concrete, Laminate, Tile, Formica, MDF, etc) is dry; this can be done by placing a 4’X4’ plastic sheet on the substrate and taping down the edges. If after 24 hours, the substrate is still dry below the plastic sheet, then the substrate is dry enough to start coating. The plastic sheet testing is also a good method to determine if any hydrostatic pressure problems exist that may later cause dis-bonding.

3) PRODUCT MIXING: This product has a mix ratio of 12# part A to 3.85# part B for standard colors. Standard packages are in pre-measured kits and should be mixed as supplied in the kit. We highly recommend that the kits not be broken down unless suitable weighing equipment is available. After the two parts are combined, mix well with slow speed mixing equipment such as a jiffy mixer until the material is thoroughly mixed and streak free. After mixing, transfer the mixed material to another pail (the transfer pail) and again remix. The material in the transfer pail is now ready to be applied on the primed substrate. Improper mixing may result in product failure.

4) PRIMING: This product is only intended as a high solids primer suitable for most substrates. However, if the surface is very porous, then a lower solids primer might be more suitable to reduce the possibility of air release problems occurring. Contact your Spartan Epoxies sales rep for more information.

5) PRODUCT APPLICATION: The mixed material can be applied by brush or roller. However, the material can also be applied by a suitable serrated squeegee and then back rolled as long as the appropriate thickness recommendations are maintained. Maintain temperatures and relative humidity within the recommended ranges during the application and curing process. If concrete conditions or over aggressive mixing causes air entrapment, then an air release roller tool should be used prior to the coating tacking o to remove the air entrapped in the coating. Thinner applications will not level as well as higher build applications.

6) RECOAT OR TOPCOATING: Although a topcoat is recommended, it is optional. Many topcoats are suitable for placement over this coating including both urethanes and epoxies. When top coating this product, you must first be sure that the coating has tacked o before top coating can commence. Before top coating, check the coating to verify no epoxy blushes were developed (a whitish, greasy film or de-glossing). If a blush is present, it must be removed prior to top coating. A standard type detergent cleaner can be used to remove any blush. Many epoxy coatings and urethanes are compatible for use as a topcoat for this product as well as multiple coats of this product as an intermediate build coat.

7) CLEANUP: Xylol is the most effective, but if you wish not to use xylol, you can use acetone or alcohol. Xylol is the best and most recommended. Remember to protect your skin and eyes.

8) CLEANING: Caution! Some cleaners may affect the color of the epoxy installed. Test each cleaner in a small area, utilizing your cleaning technique. If no ill effects are noted, you can continue to clean with the product and process tested.

9) RESTRICTIONS: Restrict the use of the surface to light traffic and non-harsh chemicals until the coating is fully cured (see technical data under full cure). It is best to let the floor remain dry for the full cure cycle. Dependent on actual complete system application, the surface may be slippery, especially when wet or contaminated; keep the surface clean and dry.

Preparation, Mixing and Installation Instructions for SPE-META-UV / 100% CLEAR EPOXY BINDER System.

1.) PRODUCT STORAGE: Store product in an area so as to bring the material to normal room temperature before using. Continuous storage should be between 60 and 90 degrees F. Low temperatures or temperature fluctuations may cause crystallization.

2.) SURFACE PREPARATION: The most suitable surface preparation would be a fine brush blast (shot blast) to remove all laitance and provide a suitable profile. All dirt, foreign contaminants, oil, and laitance must be removed to assure a trouble free bond to the substrate. A test should be made to determine that the substrate (Concrete, Laminate, Tile, Formica, MDF, etc) is dry; this can be done by placing a 4’X4’ plastic sheet on the substrate and taping down the edges. If after 24 hours, the substrate is still dry below the plastic sheet, then the substrate is dry enough to start coating. The plastic sheet testing is also a good method to determine if any hydrostatic pressure problems exist that may later cause disbanding.

3.) PRODUCT MIXING: When mixing metallics take part B, open and pour into bucket, next open Metallic container and slowly pour into part B while mixing thoroughly. Make sure metallics achieve wetness. Once all metallics are mixed thoroughly add Part A and again mix thoroughly. To prevent air from being introduced into the epoxy, DO NOT lift mixing blade out of epoxy while mixing. This product has a mix ratio of 9.0# part A to 4.15# part B. Standard packages are in pre-measured kits and should be mixed as supplied in the kit. We highly recommend that the kits not be broken down unless suitable weighing equipment is available. After the two parts are combined, mix well with slow speed mixing equipment such as a jiffy mixer until the material is thoroughly mixed and streak free. After mixing, transfer the mixed material to another pail (the transfer pail) and again remix. The material in the transfer pail is now ready to be applied on the primed substrate. Improper mixing may result in product failure.

4.) PRIMING: A suitable primer should be used before applying this product. See the front side of this technical data for primer information. If a primer is not used, more porous substrates may cause outgassing and possible surface defects.

5.) PRODUCT APPLICATION: The mixed material can be applied by brush or roller. However, the material can also be applied by a suitable serrated squeegee and then back rolled as long as the appropriate thickness recommendations are maintained. Maintain temperatures and relative humidity within the recommended ranges during the application and curing process. If concrete conditions or over aggressive mixing causes air entrapment, then an air release roller tool should be used prior to the coating tacking off to remove the air entrapped in the coating. This product can be used with various colored sand in a broadcast system or other suitable aggregate can be used in conjunction with this product to achieve a variety of color and application patterns. When using as a broadcast binder, always evaluate performance parameters with a test area which is dependent on aggregate size and thickness, prior to application. Contact your representative for details as necessary.

6. RECOAT OR TOPCOATING: If you opt to recoat or topcoat this product, you must first be sure that the coating has tacked o before recoating. Always remember that colder temperatures will require more cure time for the product before recoating or top coating can commence. Before recoating or top coating, check the coating to ensure no epoxy blushes were developed (a whitish, greasy film or de-glossing). If a blush is present, it must be removed prior to top coating or recoating. Many epoxy coatings and urethanes are compatible for use as a topcoat for this product as well as multiple coats of this product.

7) CLEANUP: Use xylol.

8) CLEANING: Caution! Some cleaners may affect the color. Test each cleaner in a small area. If no ill effects are noted, you can continue to clean with the product and process tested.

9) RESTRICTIONS: Restrict the use of the epoxy to light traffic/use, and non-harsh chemicals until the coating is fully cured (see technical data under full cure). It is best to let the floor remain dry for the full cure cycle. Dependent on actual complete system application, the surface may be slippery, especially when wet or contaminated; keep the surface clean and dry.

Reviews Over METALLIC EPOXY - 800 FT² KIT

Total Reviews (1)

From the moment I called Spartan Epoxies and spoke with Mike, I knew we were in good hands. Mike's expertise and genuine willingness to assist were evident from the start. He listened to what I envisioned and knew right away what I needed.

Mike knew I haven't used epoxy before—so he offered his phone number and email address and encouraged me to reach out with any questions I had along the way. His background as a skilled installer brought decades of insight and expertise, making me feel confident I had resource to reach out to if we had questions along the way.

The product itself exceeded our expectations. The kit assembled by Mike was comprehensive and contained all the necessary tools and materials for a seamless installation process. Despite moments of uncertainty during the application, we trusted the process, and the results speak for themselves. Our flooring turned out exactly as we envisioned – a stunning, custom creation that perfectly complements the 'moody vibe' of our bathroom.

Not only is our new flooring aesthetically pleasing, but it's also remarkably durable and easy to maintain. There is no grout to clean, no seams to deal with, is waterproof, etc. Its unique design has become a focal point in our home, garnering compliments from all who visit. We couldn't be happier with the outcome.

As a Realtor in Oregon that tours thousands of homes a year, I can confidently say that epoxy floors will be making a tremendous presence in 2024 as more people begin to realize they can create custom flooring masterpieces without the use of saws, tile saws, specialty skills, etc--all while increasing the value of their home and adding 'flavor' to their space.

I wholeheartedly recommend Spartan Epoxies to anyone seeking professional-grade products, unparalleled customer service, and exceptional results. Our experience with Mike and the Spartan Epoxies team was nothing short of outstanding, and we are grateful for their professionalism, integrity, and commitment to customer satisfaction.

Thank you, Spartan Epoxies, for helping us turn our flooring dreams into a reality.